Why Factory Testing Matters: Your First Line of Defense

Each power transformer represents a significant investment and decades of operational responsibility. At our accredited labs, we subject each unit to >20 distinct tests before release. Why? Because field failures cost 10x more than rigorous factory testing, and 92% of transformer failures trace back to undetected manufacturing defects. Our testing philosophy exceeds IEC 60076, IEEE C57.12, and country-specific standards like ANSI/NEMA – delivering certified reliability from the factory floor to your substation.

Routine Tests: Mandatory Verification for Every Unit

(Performed on 100% of production units)

Winding Resistance Measurement

- Verifies DC resistance balance (≤2% phase imbalance, ≤1% line imbalance)

- Detects loose connections, broken strands, or contact issues in tap changers

- Our method: Precision 4-wire Kelvin bridge with temperature mapping

Voltage Ratio & Vector Group Verification

- Confirms turns ratio accuracy at all tap positions (within ±0.5%)

- Validates phase displacement (e.g., Dyn11, YNd5) via digital phase analyzer

- Equipment: Automatic TRT-Micro test systems with graphical vector display

No-Load Loss & Current (Open Circuit Test)

- Measures core losses at 10%-115% rated voltage

- Verifies core assembly quality, lamination defects, or interturn shorts

- *Our innovation: Harmonic-corrected loss calculation per IEC 60076-19

Load Loss & Impedance (Short Circuit Test)

- Quantifies copper losses at principal taps (corrected to 75°C)

- Determines critical % impedance tolerance (≤±7.5% per IEEE C57.12.90)

- Data application: Basis for fault current coordination studies

Dielectric Strength Validation

- Lightning impulse test (1.2/50μs wave): Up to 650kV peak for 220kV class

- AC withstand test: 50Hz applied voltage for 60 seconds

- Partial discharge monitoring: ≤5pC at 1.5x operating voltage

Type Tests: Design Validation on Prototypes

(Conducted on first-of-series units)

Temperature Rise Test

- Validates cooling system performance per IEC 60076-7

- Confirms hot-spot temps ≤95°C (oil) / ≤140°C (dry-type) at 120% load

- *Test duration: 12-24 hours until thermal equilibrium

Lightning Chopped Wave Test

- Simulates steep-front surges (3-6μs chop time)

- Critical for transformers in lightning-prone regions

Short-Circuit Withstand Verification

- Proves mechanical stability under worst-case fault currents

- Post-test diagnostics: Frequency response analysis (FRA) to detect coil movement

- *Our capability: 8,000MVA short-circuit generator

Special Tests: Application-Specific Validation

(Customized per client requirements)

Harmonic Loss Evaluation

- Quantifies additional losses from nonlinear loads (e.g., data centers, VFDs)

- Measures eddy losses up to 2kHz using wideband power analyzers

Seismic Qualification (IBC 2018)

- Zone 4 simulation on 6-DOF shaker tables

- Certification: IEEE 693-compliant for California/Oregon projects

Transport Simulation Testing

- Vibration testing: 5-500Hz sweep at 3g RMS

- Shock testing: 10g vertical impact simulation

- 👉 Download our [Transport Simulation Report] for logistics planning

Extended Partial Discharge Monitoring

- 12-hour ACLD test (IEC 60270) at 1.7Ur

- Acceptance threshold: ≤5pC for 220kV units

Beyond Standards: Our Proprietary Test Protocols

Digital Twin Verification

- Compares FRA signatures against design simulations

- Creates baseline for future condition monitoring

Oil Diagnostics 360°

- DGA (Dissolved Gas Analysis): 9-gas chromatography

- Particle count: NAS 1638 Class 6 compliance

- Moisture: ≤10ppm via Karl Fischer titration

Thermal Imaging Audit

- FLIR T1040 scans of bushings, radiators, and core joints

- Detects hotspots >2°C above ambient

Why Our Testing Protocol Wins Projects

| Competitor Standard | Our Protocol | Client Impact |

|---|---|---|

| Basic routine tests | Routine + Type + Special tests | Eliminates 99.5% infant mortality |

| Manual recording | Blockchain-secured digital records | Tamper-proof lifetime documentation |

| Isolated component tests | System-level validation under load | Guaranteed grid compatibility |

| Post-test sampling | 100% oil chemistry DGA | Zero oil-processing delays at site |

Your Next Steps to Risk-Free Procurement

- Specification Support: Use our [Test Plan Builder Tool] to generate project-specific checklists

- Witness Testing: Reserve slots for your quality team via [Remote Testing Portal]

- Certification Access: Download sample reports:

Ready to specify transformers with validated reliability?

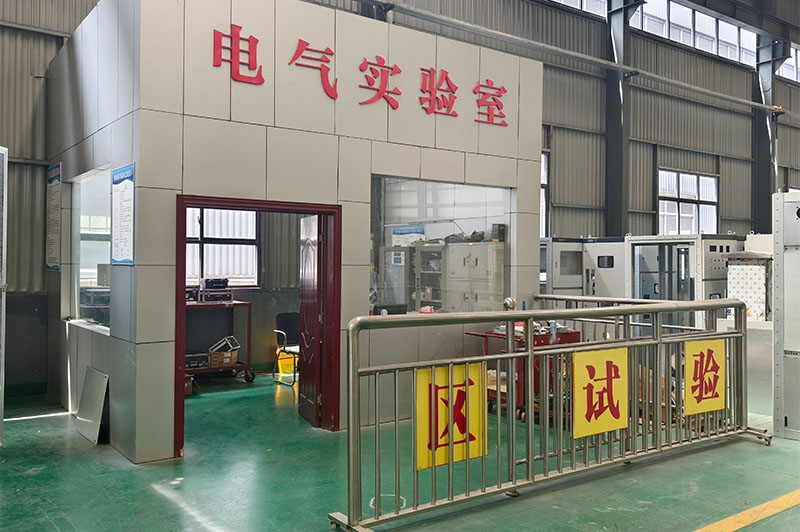

→ [Explore Our Test Facilities]

→ [Request Your Custom Test Protocol]

→ [Download Transformer Testing Whitepaper]